Tonight I got started on tailcone assembly. 2.5 man hours

Anti wear block riveting.Machine countersinking the nutplate attach holes.

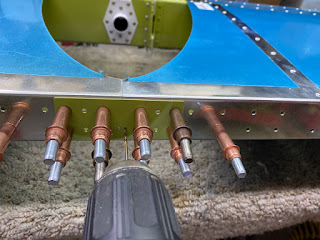

Using the vice and a socket to squeeze the bushing into place.

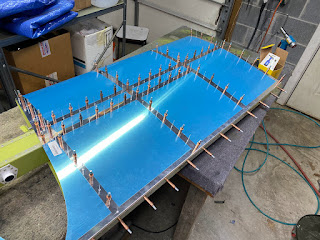

Followed the directions and used the squeezer to get to all these rivets. I could not get the ones that are not highlighted (disregard the nutplates) without a 3" yoke so I just used the rivet gun and my tungsten bucking bar to set these rivets the old fashioned way. Some of the rivets called out by Van's are too short. I used my experience to pick the correct length. There are some blind rivets used here that at first seem unnecessary but they are not possible to squeeze due to interference. I could have bucked them the traditional way but decided to go with the Van's plan.