Continued the prep for the fuel tank assembly.

They have you cleco all the ribs into the top skin. Then cleco the bottom skin onto the assy.Then the fuel inlet is match drilled to the assy. At first I cleco'ed the unit to the skin but it left a huge gap. So I removed the clecos and just held it into place while match drilling up to #30. This virtually eliminated the gap :)

There is one hole that must be drilled and cleco'ed from the inside.

And then you bend the fuel level sender per the directions. The sender I received was not made like the one in the KAI's. Therefore I just made it look as close as possible to the full size template in the directions.

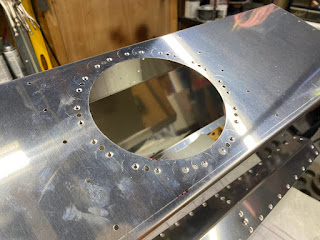

Next I had to countersink the nutplate attach rivet holes in the inspection cover. Make sure the little notch is on the left of the large notch at the bottom.

Then they have you rivet the nutplates to the cover. I only have a 2.5" yoke so two of the rivets could not be squeezed. So instead I just back riveted those two with the rivet gun and back rivet set that I have used for prior projects.