Working on vertical stabilizer rear spar parts. - 2.5 man hours

Splitting the rudder attach/bearing brackets apart. The tabletop band saw does a great job. I use a wood cutting blade instead of a fine tooth metal cutting blade on this thin aluminum. It does not clog up like the fine teeth of the metal cutting blade.Deburring the edges with the Scotchbrite wheel. This does a great job. I remove all the shear marks, flashing from cutting the parts apart, round over the edges and the corners.

For all the pre-drilled holes, I use a reamer to make em final size. This is the #12 holes that will get bolts when the bracket is attached to the spar.

Separating the VS Aft Spar upper and lower cap strips.

Marking a weird amount of material to remove from the top end of the bottom spar cap strips. Have no idea why they leave this to the builder. (Edit: I was reminded that the press brake tooling needs something to work against to form the radius in the part. Makes sense now!). They also don't give all the dimensions for the cut, they assume you will just know to follow the existing edge down to the notch in the part on the end.

Deburring and rounding the long edges.

Marking the alignment line for the upper spar caps. Get this right or you will have edge distance issues.

These lines are to be centered up in the predrilled holes in the spar web to locate the upper spar caps.

Locate the bottom spar caps by aligning their bottom edge with the spar bottom edge. Use plenty of clamps.

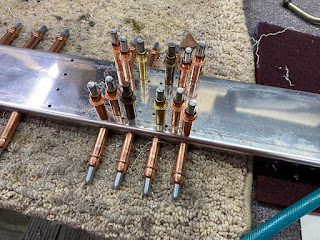

Match drill the #30 holes about every 4th hole. Use the spar web as a guide to drill the spar caps. I am a cleco in every hole I drill kind of builder.

Went back and match drilled the remaining #30 spar web to spar cap holes. Like I said, I like to use allot of cleco's. Seems to help keep stuff aligned.

Then came the match drilling of the #12 holes that will receive bolts later when the hinges are bolted on. I have a long #12 bit that makes it easier to drill in close quarters.