Next I plugged the tank lines, connected the two engine fuel lines together and then pressurized the system to 45psi. I found some leaks in easy to get to places and I had also forgotten to torque the fuel filter bypass line.

Once the big leaks were fixed, I checked every connection with SNOOP (glorified soapy water). Detected a couple very small leaks and once those were fixed, the system held pressure for 24hrs.

Thankfully the two fittings that go thru the firewall behind the rudder pedals were not leaking. I used a borescope to inspect the SNOOP coated connections.

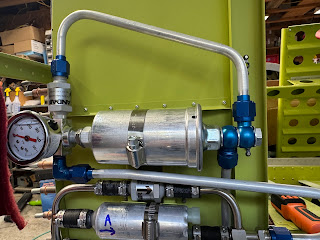

During this process, I realized that air will not flow backwards thru the pump assembly and obvious check valves. I had a leak on the suction side of the pumps and this went undetected by the original pressure gauge installed in the fuel pressure transmitter block. So I added another pressure gauge to the low point drain block. This worked great.